An interesting article from Aeroqual on the differences between Electrochemical (EC) and Heated Metal Oxide Sensors (HMOS) for measuring ozone.

ELECTROCHEMICAL (EC) OZONE SENSORS

In an electrochemical sensor, ozone gas diffuses across a porous membrane into a cell containing electrolyte and electrodes. When ozone comes into contact with the electrolyte, a change in electrochemical potential occurs between the electrodes causing electrons to flow.

In zero air, little or no electron flow occurs. As the presence of ozone increases, the electrical signal increases proportionally. The sensor interprets this signal and outputs the ozone concentration in ppm (parts per million) or ppb (parts per billion).

Strengths

- Linear Response

- Good repeat-ability and accuracy

- Fast response time – 1-2 Seconds

- Low power consumption

- Able to measure up to 20 ppm

- Limited cross interference from VOCs

Weaknesses

- Humidity can affect sensor readings

- Changes in temperature can affect sensor readings

- Sensitive to EMF/RFI

- Limited sensor life (often max of 12-18 months)

- Sensors age even when in storage

- Reduced accuracy at low ozone levels (below 0.1 ppm)

- Almost 100% cross sensitive to NO2

Applications

- Detecting ozone leaks

- Health and safety monitoring (above 0.1 ppm)

- Controlling alarms, ozone generators etc (above 0.1 ppm)

HEATED METAL OXIDE SENSORS (HMOS)

In heated metal oxide sensors a metal substrate is heated which allows it to become very sensitive to ozone gas. An electrical current passes through the metal substrate. The resistance of the current changes according to the mount of gas present. The sensor outputs the resistance in ppm or ppb.

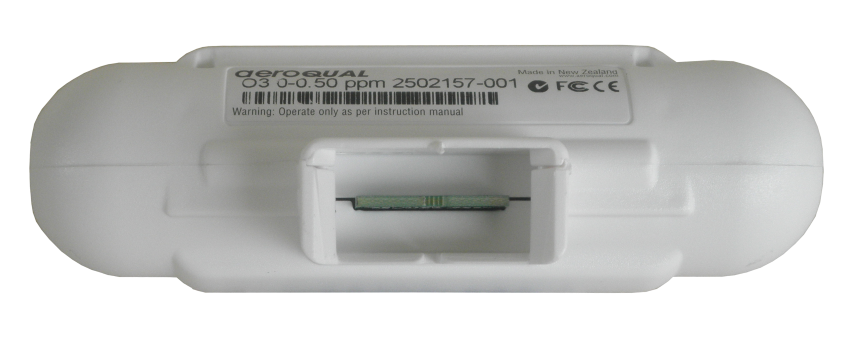

There are several kinds of HMOS sensors on the market. Different metals and temperature management can have a significant impact on the overall performance of the sensor. Aeroqual’s proprietary technology is branded GSS (gas sensitive semiconductor) to distinguish it from other HMOS available.

The following strengths and weaknesses apply to a state of the art HMOS sensor.

Advantages

- Very responsive to low levels of ozone ozone (below 0.1 ppm)

- Excellent repeat-ability and accuracy

- Long sensor life if stored properly

- Very low cross interference from NO2

Disadvantages

- Requires time to warm up (10 minutes after first use)

- Slower response time (60 seconds)

- Higher power consumption

- Cross sensitive to VOCs

- Reduced linearity above 1 ppm

Applications

- Ambient (outdoor) ozone monitoring

- Health and safety monitoring (especially below 0.1 ppm)

- Portable ozone monitoring (especially below 0.1 ppm)

- Ozone control scenarios (especially below 0.1 ppm)

WHICH IS THE BEST OZONE SENSOR?

That really depends on the application.

Electrochemical sensors are less affected by VOC cross-interference than HMOS sensors, but they are extremely (almost 100%) sensitive to NO2 and Cl2. Therefore electrochemical sensors are best suited to indoor and industrial applications while less suited to ambient outdoor applications.

Reliability above 0.1 ppm makes electrochemical sensors a good choice for health and safety monitoring. The speed of response and wide range makes them a sensible option for leak detection.

HMOS like Aeroqual’s GSS O3 sensor show excellent accuracy and stability below 0.1 ppm. Health and safety regulations around the world are moving towards lower and lower O3 thresholds. If the threshold is below 0.1 ppm then HMOS is really the only option.

In ambient outdoor air monitoring ozone levels are often below 0.1 ppm (100 ppb) so again HMOS are the better choice – especially when you consider the cross sensitivity of electrochemical sensors to NO2 which is nearly always present in ambient air monitoring.

You can read the full article on Aeroqual’s website: http://www.aeroqual.com/electrochemical-sensors-hmos

Ozone Gas Monitors can be found on our Gas Sensings website.

Hi. I would like to speak to someone who can walk me through whether EC ozone sensors or HMO sensors are better for measuring ozone close to the source of the gases being produced. Specifically, what risks do you believe exist with each type of sensor to measure other gases/hydroxyls as well as ozone when more than just ozone is being created (thereby incorrectly reporting a higher measured level of ozone)? Thank you in advance for your assistance.