Aromatic isocyanates are a group of chemical compounds with unique properties and versatile applications in various industries. These compounds, characterized by the direct attachment of the NCO group to an aromatic ring, have gained significance in the world of chemistry and manufacturing. In this blog post, we will delve into the world of aromatic isocyanates, discussing their properties, applications, potential health risks, and the importance of accurate measurement and calibration.

What Are Aromatic Isocyanates?

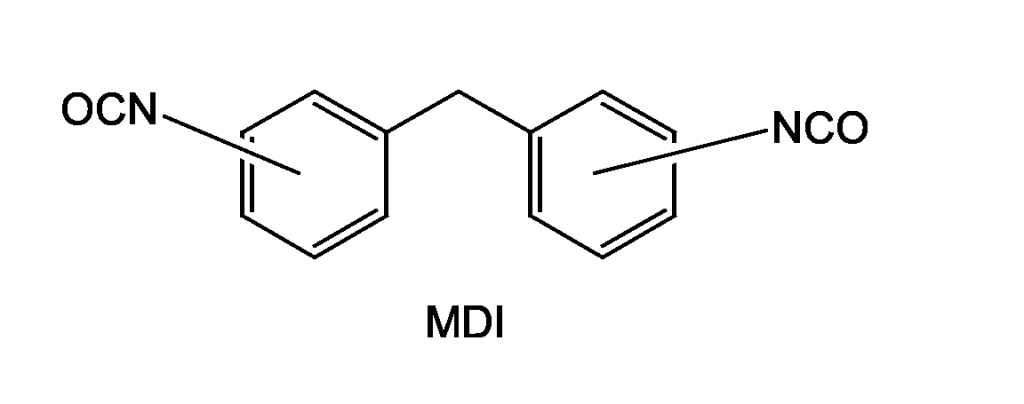

Aromatic isocyanates, as the name suggests, are isocyanates with an aromatic ring structure. Two of the most common aromatic isocyanates are TDI (toluenediisocyanate) and MDI (methylenediphenyl diisocyanate). They play a pivotal role in the production of various materials, including polyurethane and polyurea foams, elastomers, adhesives, and coatings. Aromatic isocyanates are preferred in applications where color stability and UV resistance are not primary concerns. One notable characteristic of these compounds is their rapid reactivity with polyols under catalyzed conditions, making them essential in many manufacturing processes.

Health Risks Associated with Aromatic Isocyanates

While aromatic isocyanates offer numerous benefits, it is crucial to be aware of the potential health risks associated with them. Exposure to chemicals with low vapor pressures, such as aromatic isocyanates, can occur through skin contact with contaminated solvents or surfaces. Additionally, these compounds present a respiratory sensitization hazard, making it essential for workers and individuals handling them to take necessary precautions.

Measuring Aromatic Isocyanates

Accurate measurement and calibration of aromatic isocyanates are critical to ensure safety and quality in various industries. Different types of sensors and calibration procedures are used for this purpose. Here’s a brief overview of how you can measure and calibrate aromatic isocyanates:

- Fixed Mount Sensors: These sensors are permanently installed in specific locations to continuously monitor and detect the presence of aromatic isocyanates in the environment.

- Handheld Sensors: Portable devices that allow for on-the-spot measurements, making them ideal for field applications.

- Dissolved Kits: These kits are designed for analyzing aromatic isocyanates in liquid samples, providing a solution for various laboratory and industrial requirements.

- Replacement Sensors: Periodically replacing sensors is essential to maintain accurate measurements. Be sure to choose the right sensor for your specific needs.

- Calibration Gas: Calibration gas is used to calibrate sensors and ensure their accuracy in detecting aromatic isocyanates.

- Rentals: Some companies offer sensor rental services, allowing you to use the necessary equipment for a specific period, reducing the initial investment.

All of our monitors and dissolved kits can be found here: https://www.gas-sensing.com/support/gas-information/aromatic-isocyanates.html

Calibration Services

To maintain the accuracy and reliability of your gas measurements, annual calibration is essential. Calibration ensures that the sensors are performing within the manufacturer’s standards. Different manufacturers have specific calibration procedures and costs associated with their equipment. Here’s an approximate overview of calibration costs:

- Calibration Fee: $150

- Analyzer Calibration Fee: $300

- PM Calibration Sensor Fee: $330

- Genie Calibration Fee: $265

- ATI Calibration Fee: $205

Please note that these prices may be subject to change depending on labor and parts required. Accurate calibration is vital to ensure that your sensors are providing precise measurements and upholding safety standards.

Aromatic isocyanates play a crucial role in the production of a wide range of materials, making them indispensable in various industries. However, it is essential to be aware of their potential health risks and to invest in accurate measurement and calibration equipment to ensure safety and product quality. Whether you need fixed mount sensors, handheld devices, or calibration services, choosing the right products and services is critical. Feel free to contact us for assistance in selecting the best equipment for your specific application.