Introduction:

In the complex world of industrial water treatment and power generation, the quest for effective corrosion inhibitors is relentless. Molybdate, also known as the Molybdate Ion (MoO42-), has emerged as a key player in this arena, providing a safe and environmentally friendly alternative for corrosion control in open and closed-loop cooling water systems. In this blog post, we will explore the various facets of Molybdate, from its chemical formula to its industry uses, health risks, regulations, and the methods for measuring its concentration.

Other Names, Chemical Formula, and CAS Number:

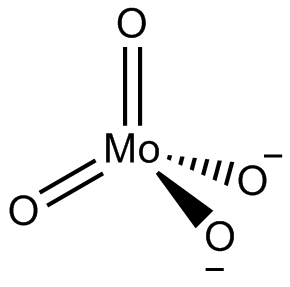

- Other Names: Molybdate Ion

- Chemical Formula: MoO42-

- CAS Number: 14797 – 55 – 8

Industry Uses:

Molybdate finds its niche in the industrial water treatment and power generation sectors, specifically as a corrosion inhibitor in both open and closed-loop cooling water systems. In solution, Molybdate ions form a complex with oxidized iron, creating a protective film of molybdate and ferric-oxide. This film acts as a shield against corrosion, contributing to the longevity and efficiency of cooling water systems. Notably, Molybdate serves as a viable and environmentally acceptable alternative to chromate treatment, marking a significant step towards sustainable industrial practices.

Health Risks:

One of the remarkable aspects of Molybdate is its low or even negligible toxicity. Unlike many other transition elements, exposure to Molybdate poses no significant health risks. This characteristic enhances its appeal as a corrosion inhibitor, offering effective protection without compromising on safety.

Regulations:

As of now, there are no listed regulations or restrictions for the concentration of Molybdate in water. This lack of regulatory constraints further underscores its versatility and acceptance in industrial applications. Industries can utilize Molybdate without navigating stringent regulations, streamlining its integration into existing processes.

Measuring Molybdate:

All of those units can be found here: https://www.gas-sensing.com/information/molybdate

Accurate measurement of dissolved Molybdate concentration in water is crucial for maintaining optimal corrosion inhibition levels. The concentration is typically measured in units of parts per million (ppm). To facilitate this, instrumental kits from CHEMetrics are available, offering a reliable means of determining Molybdate levels in water. These kits cover a range of concentrations, from 0-7 ppm to 20-200 ppm, providing flexibility to industries based on their specific needs.

Conclusion:

In the realm of corrosion inhibition, Molybdate stands out as a versatile and environmentally friendly solution. Its efficacy in forming protective films, coupled with its low toxicity and absence of stringent regulations, positions it as a preferred choice for industries engaged in water treatment and power generation. As we strive for sustainable industrial practices, Molybdate’s role as a corrosion inhibitor marks a significant step towards achieving this goal. Consider incorporating Molybdate into your industrial processes to benefit from effective corrosion control without compromising on safety or environmental responsibility.