The store will not work correctly in the case when cookies are disabled.

Making sense of the air we breathe.

| We provide Gas Sensors for every workplace, or safety need. |

|

|

| Our Top Selling Gas Sensors |

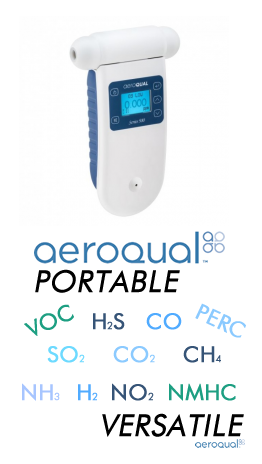

Aeroqual Series-500 offers interchangeable sensor heads and integrated data logging.

ATI D16 is the best and fastest leak detection sensor we have tested.

The A14 offers remote gas detection, control and alarm capability at a competitive price

SM-70 gas sensor is a wall mount sensor with audible alarm and controls

GasAlert Solo is a popular personnal safety sensorS

|

Portable Gas Sensors

Portable Gas Sensors Fixed Mount Gas Sensors

Fixed Mount Gas Sensors Replacement Sensors

Replacement Sensors Accessories

Accessories Dissolved Meters

Dissolved Meters

Work place safety alarm

Work place safety alarm Personal safety sensor

Personal safety sensor