D-12 Toxic Gas Monitor

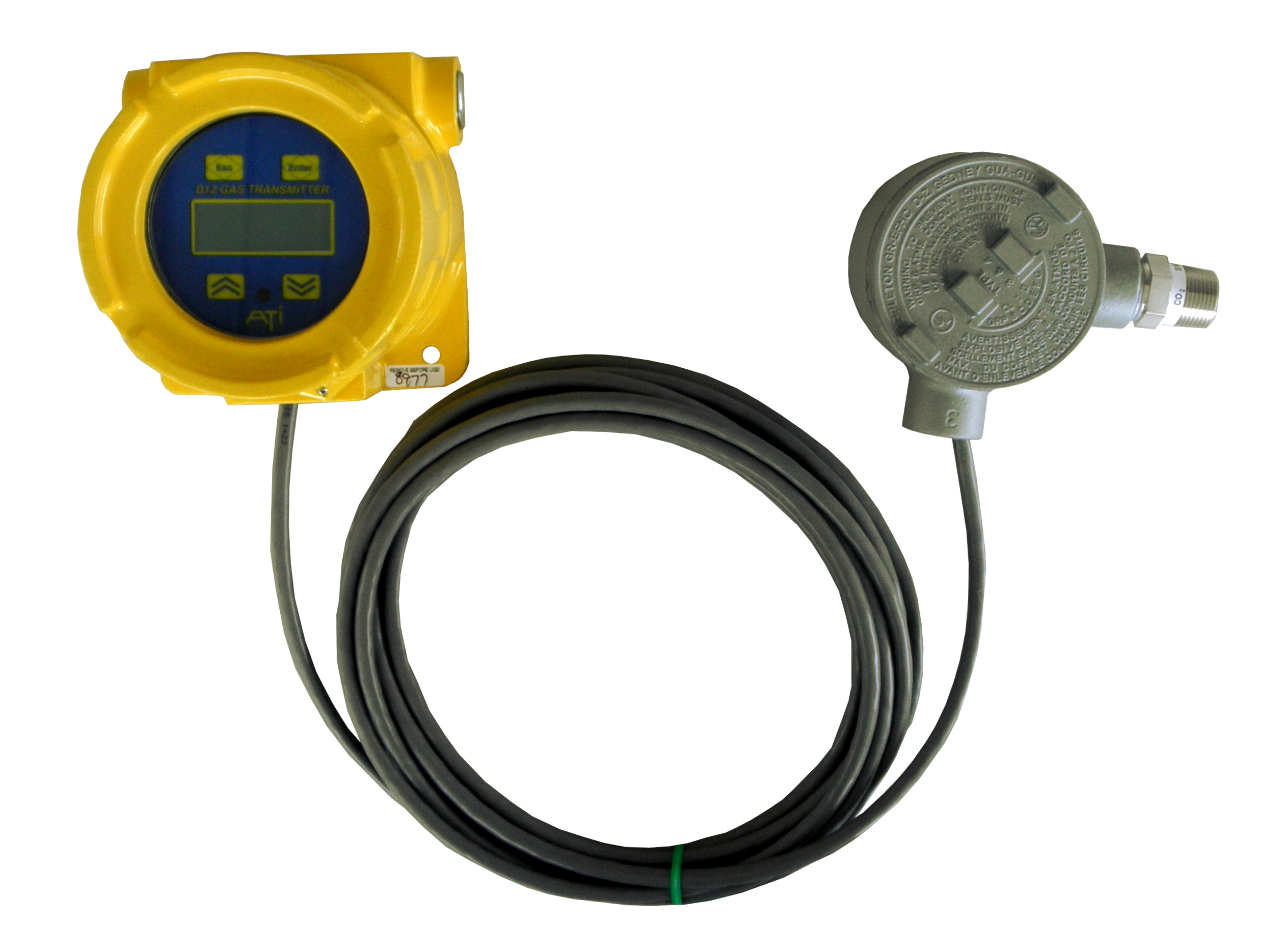

ATI's D12 Toxic Gas Transmitter will accept up to 46 different sensors, greatly reducing the need for multiple transmitter models. The self-aligning sensor holder simply plugs in, with automatic sensor recognition and verification when contact is made.

D12 Features:

-LCD Graphics Display: Gas concentrations are displayed in large, easy to read numbers. The display also provides alarm indication and complete menus for setting up operating parameters. A backlight is available when operating in 3-wire mode.

-Internal Data Logger: Measured gas values are stored at user definable intervals and can be recalled when needed on the LCD display. Data can be downloaded using the MODBUS™ interface.

-Non-Intrusive Operation: Operating functions such as calibration, alarm setup, alarm reset, data view, and setup options are all available using a magnetic tool. It is not necessary to open the enclosure when making adjustments.

-Password Protection: Program settings stored in the transmitter may be protected by a user selectable 4-digit password. Operators may still review all functions, but changes may only be made by authorized personnel.

-Modular Electronics: The D12 electronic assembly plugs easily into the power supply board in the base of the enclosure. Transmitters can be removed for wiring and quickly replaced in the event of a fault condition.

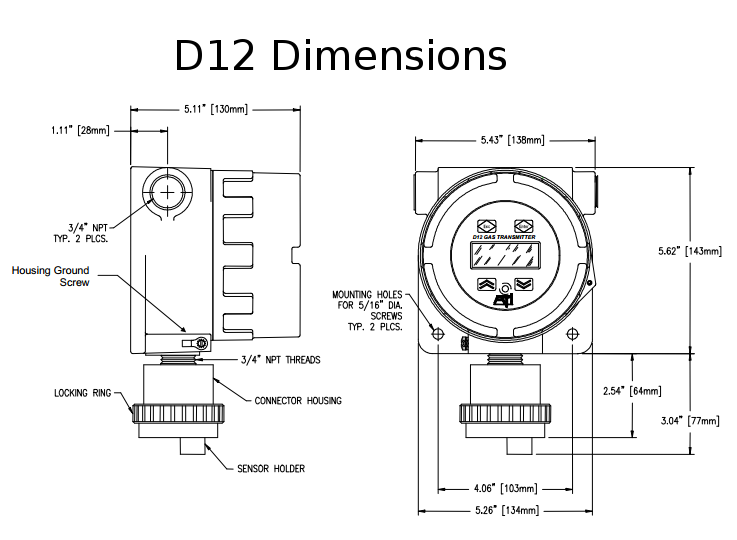

-Explosion Proof Enclosure: Transmitters are designed for operation in hazardous areas. The cast aluminum housing for the D12 transmitter is rated for Class 1, Division 1, Group B, C, D locations and is UL, FM, and CSA certified.

-Scalable 4-20 mA: The output range for a particular sensor is programmable within the range boundaries set in that sensor.

-Three Internal Alarm Relays: Optional relay outputs can be used for local alarm functions. All relays are programmable for set point, hysteresis, on-delay, off-delay, and other variables. Even a remote reset feature is provided for in the transmitter design.

-Analog Output Simulation: Transmitter analog output can be set to user definable values. This provides for complete loop testing without the need to apply gas to the sensor.

-Relay Output Simulation: Alarm relays may be activated on command to allow testing of local alarm devices. Any combination of relays may be activated based on operator selection. Output and alarms may also be inhibited for maintenance and calibration.

-Serial Communication Interface: The transmitter is available with either HART™ or MODBUS™ protocol. The HART™ protocol supports the HART™ Universal and Common Practice Commands at 1200 baud using the Bell 202 FSK modem standard. The MODBUS™ protocol supports 9600 baud access to concentration and status information, and supports alarm setup and many other functions on either RS485 or RS232 (software selectable).

The D12 offers easy to use push buttons to scroll through the menus on the display. Simply remove the cover by unscrewing off the enclosure.

D12 Summary:

D12 transmitters provide useful features that simplify installation, operation, and maintenance. From clear menu-driven setup pages to large numerical display of gas values, you simply can’t find a more versatile transmitter. Gas concentrations are displayed in large, easy to read numbers. The display also provides alarm indication and complete menus for setting up operating parameters. Backlighting is available when operating in 3-wire mode.

Operating functions such as calibration, alarm setup, alarm reset, data view, and setup options are all available using a magnetic tool. It is not necessary to open the enclosure when making adjustments.

Transmitters are designed for operation in hazardous areas. The cast aluminum housing for the D12 transmitter is rated for Class 1, Division 1, Group B, C, D locations and is UL, FM, and CSA certified.

The transmitter is available with either HART™ or MODBUS™ protocol. The HART™ protocol supports the HART™ Universal and Common Practice Commands at 1200 baud using the Bell 202 FSK modem standard. The MODBUS™ protocol supports 9600 baud access to concentration and status information, and supports alarm setup and many other functions on either RS485 or RS232 (software selectable).

D12 Options (how to order):

Note: The D12 is highly customizable to fit your every need. Please review the options closely to ensure you choose the right configuration for your application. Please call if you have any questions or need help configuring the right sensor for your application.

Sensor Module: Choose the gas and range of detection required for your application

Transmitter Type: Choose Electrochemical sensor for toxic gas applications. Choose combustible gas sensor for combustible gasses and environments. Either configuration is available with or without the optional alarm board.

Sensor Holder Style: The sensor of the D12 can be mounted in a variety of ways

- Integral holder for sensor and generator is standard and contains the standard sensor holder directly on the enclosure of the D12 out the bottom of the enclosure, includes a holder for the optional auto-test generator.

- Remote Sensor System for toxic sensors allows for a remote mount sensor at a custom length of the customers choosing, for toxic gas applications.

- -Integral Combustible gas sensor holder contains a combustible gas sensor holder directly on the enclosure of the D12 out the bottom of the enclosure.

- -Integral Combustible gas sensor with generator holder contains a combustible gas sensor holder directly on the enclosure of the D12 out the bottom of the enclosure. Includes a holder for the optional auto-test generator.

- -Remote Sensor System for combustible gas sensor allows for a remote mount sensor at a custom length of the customers choosing, for combustible gas applications.

- -Remote Sensor System for combustible gas sensor with generator allows for a remote mount sensor at a custom length of the customers choosing, for combustible gas applications, also includes a holder for the optional Auto-test generator.

-Digital Output:

- Standard 4-20 mA output is provided with all sensors

- HART interface is available for all sensors

- Modbus interface is only available for RS-485 sensors, and 115 VAC sensors.

-Accessories:

-Calibration Adapter

-Flowcell assembly

-Sensor Splash Guard

31-0162 Remote Interconnect Cable - 50ft

31-0001 Remote Interconnect Cable, Combustible Sensor - 50ft

D12 Specifications:

| Sensor Type | Electrochemical for toxic gases and oxygen. Catalytic bead for combustible gas |

| Range | User adjustable within limits of selected sensor |

| Response Time | Sensor dependent |

| Accuracy | Generally ±10% of value, but limited by available calibration gas accuracy. |

| Repeatability | ±1% (Electronic) |

| Linearity | ±0.5% (Electronic) |

| Zero Drift | Less than 2% full scale per month |

| Span Drift | Dependent on operating environment but generally less than 3% per month |

| Analog Output | Loop-powered 4-20 mA, 675 ohms maximum at 24 VDC |

| Power Requirements | 12 - 30 VDC, 25 mA maximum in loop-powered mode 12 – 30 VDC, 200 mA maximum in 3-wire mode. |

| Serial Interface: | HART™ (1200 baud modem interface ) MODBUS™ (1200-9600 – RS232 or RS485, software selectable) |

| Alarms: | Three concentrations alarms (Caution, Warning, Alarm) programmable for set point, hysteresis, alarm delay, and manual or automatic reset. One fault alarm with programmable output and relay response. |

| Alarm Relays: | Three SPDT, 5 A @ 230 VAC resistive |

| Relay Coil: | Programmable either normally energized or normally deenergized. |

| Controls: | 4 magnetic switches on front of transmitter |

| Enclosure | Explosion-proof, Class 1, Div. 1, Groups B, C, & D. |

| Display | Graphics LCD, 96w x 32h, backlit, transflective |

| Controls | Four, dome-type push buttons; Remote alarm reset input (w/optional alarm relays only) |

Downloads:

Links to more info:

ATI Specific Calibration Information

Auto-test Generator:

The Auto-test option verifies the serviceability of the transmitter on a prescribed schedule by exposing the sensor to a small amount of gas, and verifying a minimum response. Three attempts per test are made, and if the sensor does not respond on the third attempt, a fault alarm is triggered (may be optionally disabled).

The test is performed at a specific time of day, and may be scheduled to repeat every 1 to 14 days. The date and time of the next test is available for editing, and the test may be triggered manually at any time, without affecting the preset schedule.

The Auto-Test Generator can be easily added to the standard Integral Sensor Holder.

The Auto-test option requires an E18 gas generator, which must be compatible with the installed sensor’s gas type, and full-scale range. Table below lists gas compatible generators and sensors.

| Auto-test Generator | Generator Type |

Compatible Sensors |

| 00-1239 | Chlorine (Cl2) |

Bromine (Br2) |

|

Chlorine (Cl2) |

||

| Chlorine Dioxide (ClO2) | ||

| Flourine (F2) | ||

| Ozone (O3) | ||

| Hydrogen Flouride (HF) | ||

| Nitrogen Dioxide (NO2) | ||

| Iodoine (I2) | ||

| Acid Gas | ||

| 00-1240 | Ammonia (NH3) | Ammonia (NH3) |

| Dimethylamine (DMA) | ||

| 00-1241 | Carbon Monoxide (CO) | Carbon Monoxide (CO) |

| 00-1243 | Hydrogen Sulfide (H2S) | Hydrogen Sulfide (H2S) |

| Hydrogen Chloride (HCl) | ||

| 00-1244 | Sulfer Dioxide (SO2) | Sulfer Dioxide (SO2) |

| Hydrogen Cyanide (HCN) |

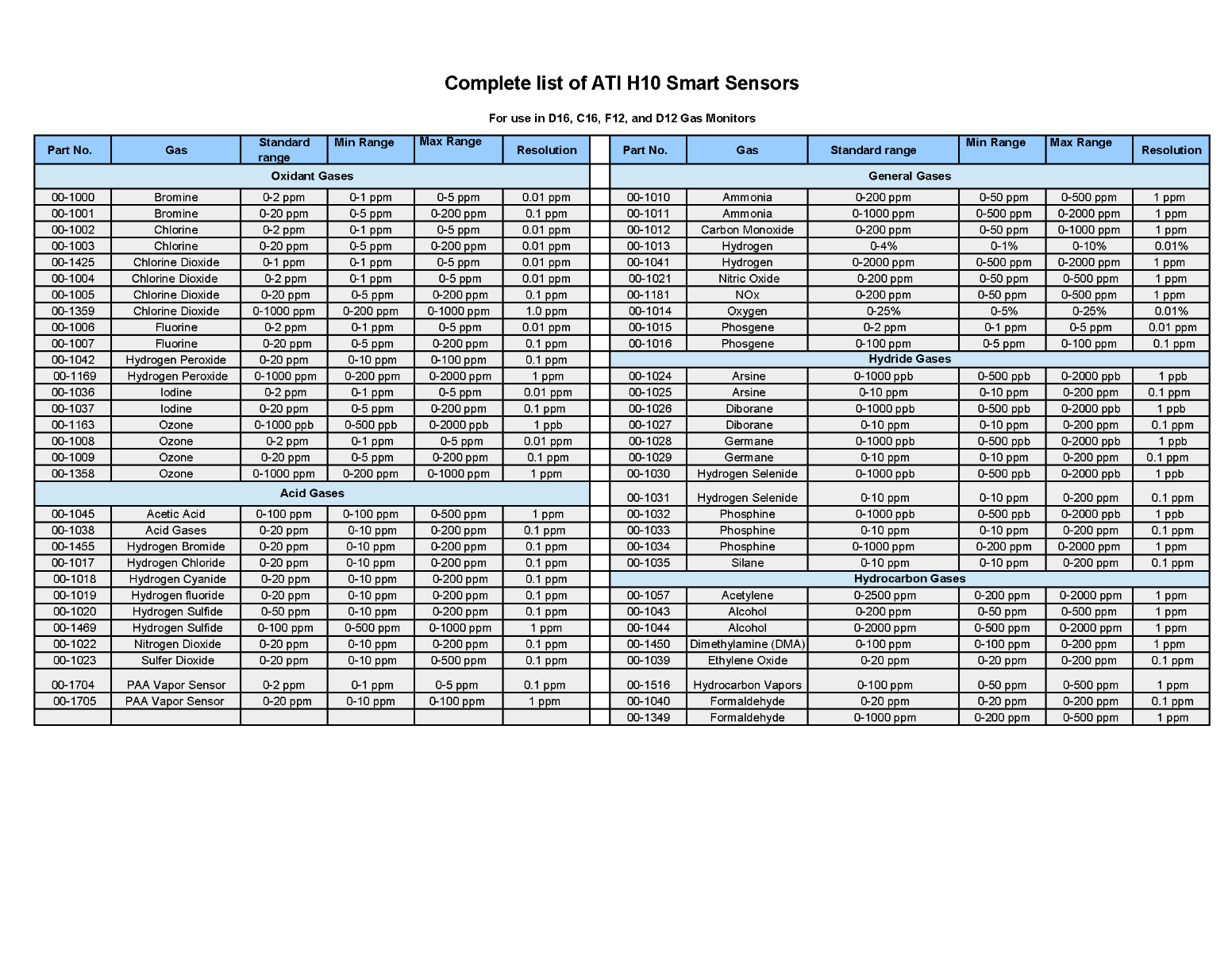

Sensors:

We provide each sensor with a standard detection range. However, for specific applications each sensor can be calibrated to custom ranges. See list below for min, and max range options for each sensor, along with standard range.

Please contact us with any questions on what sensor might be right for you, or if other sensors are available for your application.

| Manufacturer | ATI |

|---|---|

| Call For Price | No |

| Gas | Acid Gases, Acetic Acid, Acteylene (C2H2), Alcohol, Ammonia (NH3), Arsine (AsH3), Bromine (Br2), Carbon Monoxide (CO), Chlorine (Cl2), Chlorine Dioxide (ClO2), Diborane (B2H6), Dimethylamine, Ethylene Oxide (ETO), Fluorine (F2), Formaldehyde (CH2O), Germane (GeH4), Hydrocarbon (HC), Hydrogen (H2), Hydrogen Bromide (HBr), Hydrogen Chloride (HCl), Hydrogen Cyanide (HCN), Hydrogen Fluoride (HF), Hydrogen Peroxide (H2O2), Hydrogen Selenide (H2Se), Hydrogen Sulfide (H2S), Iodine (I2), Nitric Oxide (NO), Nitrogen Dioxide (NO2), Nitrogen Oxides (NOx), Oxygen (O2), Ozone (O3), Peracetic Acid, Phosgene (COCl2), Phosphine (PH3), Silane (SiH4), Sulfur Dioxide (SO2) |

| 4-20 mA Output | Yes |

| Relays | 1 Alarm Relay + 1 Control Relay |

| Field Replaceable Sensor | Yes |

| Auto Test Generator | None |

| Min, Max, Avg | No |

| Voltage Output | None |

| Power Requirements | 12-30 VDC |

| Datalogging | No |

| Rechargeable | No |

| Field Replaceable Battery | Yes |

| Warranty | 1 Year |

| Audible Alarm | No |

| Calibration | Replace Sensor After Failure |

| Sensor Life | 6 Months |

| Unit Features | -XP Class-1, Div-1 Rated -4-20 mA Output -Integrated Relay -Remote Sensor Options -Optional Auto-Test Generator -Digital Communications |

| Sensor Range | Gas Dependent |

| Resolution | Range Dependent |

| Integrated Relays | Yes |