B12 Gas Transmitter

ATIs B12 Gas Transmitter is a 4-20mA loop-powered instrument that transmit a signal linearly proportional to gas concentration.

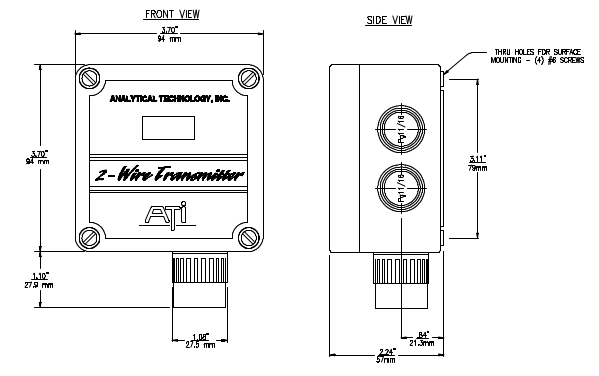

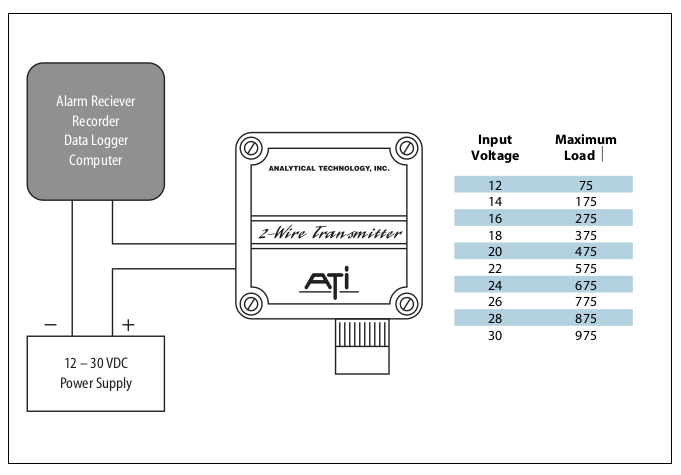

The B12 transmitters are two-wire 4-20 mA transmitters that are loop-powered to signal linearly proportional to gas concentration. They operate from a 24 VDC power supply and the transmitter will drive loads up to 675 ohms, which is sufficient for most monitoring applications. For applications that require battery operation, they can operate at 12 VDC with a reduced output load. The electrochemical sensors are designed for use in ambient air or in ventilation ducts and are not recommended for use in extremely dry air or in condensing gas streams. The sensor is located in one of the knockouts, and additional knockouts are provided on the sides of the transmitter to simplify installation.

Transmitters are normally supplied with the sensor close coupled to the NEMA 4X polystyrene enclosure. An optional LCD display can be ordered and is installed on the face of the enclosure and is great for getting the gas concentration. (NOTE: the display must be ordered at the time the order is placed; this cannot be added later).

The B12 can also be purchased in an explosion-proof transmitter enclosure that is made out of galvanized steel. Please specify that you want this enclosure by using the drop down under the Enclosure Options and selecting the Explosion-Proof Enclosure. (Picture below).

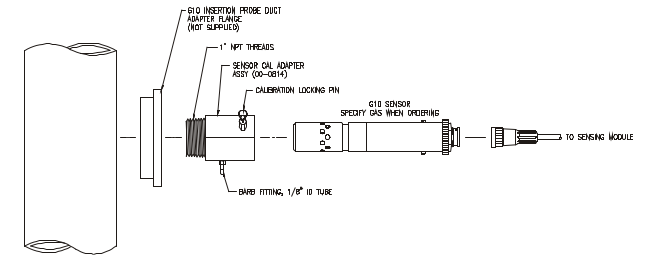

For special applications, a separate sensor can be used that allows you to be up to 25 feet away from the transmitter. Sensor duct mounting adapters can be provided which allows the sensor to be inserted into a duct or pipe through a special adapter. This allows for easy removal of the sensor for service.

Pictured above is the Flowcell assembly for the explosion-proof sensor (Part Number: 00-0298).

B12 Options (Guide to ordering)

Sensor Module:

-Choose the gas detection required for your application. Range shown is standard range; each sensor can be calibrated for a custom range for an additional $50. See chart below to see minimum and maximum detection ranges for each sensor. Contact us for details on this and to verify we can calibrate for your specific range.

Display, Enclosure & Transmitter:

-NEMA 4X - this is the standard enclosure which is suitable for many environments.

-Explosion-proof Enclosure - This version is made out of galvanized steel. The LCD display is not possible with this model.

-Explosion-proof Enclosure with Dual Condulet - Allows you to have a transmitter up to 25 feet away from the junction box.

-With LCD display - provides local indication of gas concentration (built into front of the enclosure).

-With Separated Sensor - sensor is separated from the transmitter and can be placed up to 25 feet away (cable included).

-With LCD display and separated sensor - includes the LCD display and sensor is separated from the transmitter and can be placed up to 25 feet away (cable included).

-With duct insertion sensor - Sensor duct mounting adapters allows the sensor to be inserted into a duct or pipe, and placed up to 25 feet away (cable included)

-With LCD display and duct insertion sensor - includes the LCD display and sensor duct mounting adapters allows the sensor to be inserted into a duct or pipe.

Specifications

| Accuracy | Generally ±5% of value, but limited by available calibration gas accuracy |

| Electronic Repeatability | ±1% |

| Electronic Linearity | ±0.5% |

| Zero Drift | Sensor dependent, but generally less than 1% of full scale per month, non-cumulative |

| Span Drift | Application dependent, but generally less than 3% per month |

| Output | Loop-powered 4-20 mA, 750 ohms maximum at 24 VDC |

| Power | 12-30 VDC |

| Display | None. Optional LCD display available |

| Enclosure | NEMA 4X Polystyrene Explosion-proof cast iron optional, Class 1, Div. 1, Groups B, C, & D. |

| Controls | Zero and span potentiometers mounted on transmitter circuit board |

| Operating Temperature | -30º to +55º C (except oxygen, which is -10º to +55º C) |

| Sensor Pressure Limits | 7-30 PSIA (0.5-2 Bar) |

| Calibration | Your sensor should be replaced annually |

Sensor Range Specifications:

Please contact us with any questions on what sensor might be right for you, or if other sensors are available for your application.

| Gas | Min Range | Max Range | Standard Range |

| Acetylene | 0-500 ppm | 0-2000 ppm | 0-1000 ppm |

| Acid Gases | 0-10 ppm | 0-200 ppm | 0-10 ppm |

| Alcohol | 0-500 ppm | 0-2000 ppm | 0-1000 ppm |

| Ammonia | 0-100 ppm | 0-2000 ppm | 0-100 ppm |

| Arsine | 0-1000 ppb | 0-2000 ppm | 0-1000 ppb |

| Bromine | 0-1 ppm | 0-200 ppm | 0-2 ppm |

| Carbon Monoxide | 0-100 ppm | 0-1000 ppm | 0-100 ppm |

| Chlorine | 0-1 ppm | 0-200 ppm | 0-10 ppm |

| Chlorine Dioxide | 0-1 ppm | 0-200 ppm | 0-2 ppm |

| Diborane | 0-1000 ppb | 0-2000 ppm | 0-1000 ppb |

| Ethylene Oxide | 0-20 ppm | 0-200 ppm | 0-20 ppm |

| Fluorine | 0-1 ppm | 0-200 ppm | 0-2 ppm |

| Formaldehyde | 0-20 ppm | 0-200 ppm | 0-20 ppm |

| Germane | 0-1000 ppb | 0-2000 ppm | 0-1000 ppb |

| Hydrogen | 0-1000 ppm | 0-10% | 0-4% |

| Hydrogen Chloride | 0-10 ppm | 0-200 ppm | 0-20 ppm |

| Hydrogen Cyanide | 0-20 ppm | 0-10 ppm | 0-200 ppm |

| Hydrogen Fluoride | 0-10 ppm | 0-200 ppm | 0-20 ppm |

| Hydrogen Selenide | 0-1000 ppb | 0-2000 ppm | 0-1000 ppb |

| Hydrogen Sulfide | 0-10 ppm | 0-500 ppm | 0-50 ppm |

| Hydrogen Peroxide | 0-10 ppm | 0-2000 ppm | 0-10 ppm |

| Iodine | 0-1 ppm | 0-200 ppm | 0-2 ppm |

| Nitric Oxide | 0-50 ppm | 0-500 ppm | 0-100 ppm |

| Nitrogen Dioxide | 0-10 ppm | 0-200 ppm | 0-20 ppm |

| Oxygen | 0-5% | 0-30% | 0-25% |

| Ozone | 0-1 ppm | 0-200 ppm | 0-2 ppm |

| Phosgene | 0-1 ppm | 0-100 ppm | 0-2 ppm |

| Phosphine | 0-1000 ppb | 0-2000 ppm | 0-1000 ppb |

| Silane | 0-10 ppm | 0-2000 ppm | 0-10 ppm |

| Sulfur Dioxide | 0-10 ppm | 0-200 ppm | 0-20 ppm |

Wireless Monitoring & Data Logging Kit:

Use the Wireless Monitoring & Data logging Kit with your fixed mount monitor to connect it to the internet allowing access from anywhere. Receive Instant notifications with free text and email alerts. This is a great addition for your fixed mount gas detector.

Product

Maximum Range

Minimum Range

Range

Resolution

Price

0-500 ppm

0-100 ppm

0-100 ppm

1 ppm

0-2000 ppm

0-200 ppm

0-2000 ppm

1 ppm

0-200 ppm

0-10 ppm

0-20 ppm

0.1 ppm

0-500 ppm

0-50 ppm

0-200 ppm

1 ppm

0-2000 ppm

0-500 ppm

0-2000 ppm

1 ppm

0-2000 ppm

0-500 ppm

0-1000 ppm

1 ppm

0-500 ppm

0-50 ppm

0-200 ppm

1 ppm

0-200 ppm

0-10 ppm

0-100 ppm

0.1 ppm

0-2000 ppm

0-500 ppm

0-1000 ppm

1 ppb

0-5 ppm

0-1 ppm

0-2 ppm

0.01 ppm

0-200 ppm

0-5 ppm

0-20 ppm

0.1 ppm

0-1.5%

0-0.2%

0-1%

0.01%

0-1000 ppm

0-50 ppm

0-200 ppm

1 ppm

0-5 ppm

0-1 ppm

0-1 ppm

0.01 ppm

0-1000 ppm

0-200 ppm

0-1000 ppm

1.0 ppm

0-5 ppm

0-1 ppm

0-2 ppm

0.01 ppm

0-200 ppm

0-5 ppm

0-20 ppm

0.1 ppm

0-5 ppm

0-1 ppm

0-2 ppm

0.01 ppm

0-200 ppm

0-5 ppm

0-20 ppm

0.01 ppm

0-200 ppm

0-10 ppm

0-10 ppm

0.1 ppm

0-2000 ppm

0-500 ppm

0-1000 ppb

1 ppb

0-200 ppm

0-100 ppm

0-100 ppm

1 ppm

0-200 ppm

0-20 ppm

0-20 ppm

0.1 ppm

0-20 ppm

0-5 ppm

0-20 ppm

0.1 ppm

0-5 ppm

0-1 ppm

0-2 ppm

0.01 ppm

0-2000 ppm

0-500 ppm

0-1000 ppm

1 ppm

0-200 ppm

0-20 ppm

0-20 ppm

0.1 ppm

0-200 ppm

0-10 ppm

0-10 ppm

0.1 ppm

0-200 ppm

0-10 ppm

0-1000 ppb

1 ppb

0-500 ppm

0-50 ppm

0-1000 ppm

1 ppm

0-200 ppm

0-10 ppm

0-20 ppm

0.1 ppm

0-200 ppm

0-10 ppm

0-20 ppm

0.1 ppm

0-200 ppm

0-10 ppm

0-20 ppm

0.1 ppm

0-200 ppm

0-10 ppm

0-20 ppm

0.1 ppm

0-2000 ppm

0-200 ppm

0-1000 ppm

1 ppm

0-100 ppm

0-10 ppm

0-20 ppm

0.1 ppm

0-200 ppm

0-10 ppm

0-10 ppm

0.1 ppm

0-2000 ppb

0-500 ppb

0-1000 ppb

1 ppb

0-2000 ppm

0-500 ppm

0-2000 ppm

1 ppm

0-10%

0-1%

0-4%

0.01%

0-200 ppm

0-10 ppm

0-50 ppm

0.1 ppm

0-1000 ppm

0-200 ppm

0-500 ppm

1 ppm

0-5 ppm

0-1 ppm

0-2 ppm

0.01 ppm

0-200 ppm

0-5 ppm

0-20 ppm

0.1 ppm

0-500 ppm

0-50 ppm

0-200 ppm

1 ppm

0-200 ppm

0-10 ppm

0-20 ppm

0.1 ppm

0-500 ppm

0-50 ppm

0-200 ppm

1 ppm

0-25%

0-5%

0-25%

0.01%

0-2,000 ppb

0-500 ppb

0-1000 ppb

1 ppb

0-1000 ppm

0-200 ppm

0-1000 ppm

1 ppm

0-5 ppm

0-0.01 ppm

0-2 ppm

0.01 ppm

0-200 ppm

0-0.1 ppm

0-20 ppm

0.1 ppm

0-5 ppm

0-1 ppm

0-2 ppm

0.1 ppm

0-100 ppm

0-10 ppm

0-20 ppm

1 ppm

0-100 ppm

0-5 ppm

0-10 ppm

0.1 ppm

0-5 ppm

0-1 ppm

0-2 ppm

0.01 ppm

0-200 ppm

0-10 ppm

0-10 ppm

0.1 ppm

0-2000 ppb

0-500 ppb

0-1000 ppb

1 ppb

0-2000 ppm

0-200 ppm

0-1000 ppm

1 ppm

0-200 ppm

0-10 ppm

0-10 ppm

0.1 ppm

0-200 ppm

0-10 ppm

0-20 ppm

0.1 ppm

Downloads:

| Manufacturer | ATI |

|---|---|

| Call For Price | No |

| Gas | Acid Gases, Acteylene (C2H2), Alcohol, Ammonia (NH3), Arsine (AsH3), Bromine (Br2), Carbon Monoxide (CO), Chlorine (Cl2), Chlorine Dioxide (ClO2), Diborane (B2H6), Ethylene Oxide (ETO), Fluorine (F2), Formaldehyde (CH2O), Germane (GeH4), Hydrogen (H2), Hydrogen Chloride (HCl), Hydrogen Cyanide (HCN), Hydrogen Fluoride (HF), Hydrogen Peroxide (H2O2), Hydrogen Selenide (H2Se), Hydrogen Sulfide (H2S), Iodine (I2), Nitric Oxide (NO), Nitrogen Dioxide (NO2), Oxygen (O2), Ozone (O3), Phosgene (COCl2), Phosphine (PH3), Silane (SiH4), Sulfur Dioxide (SO2) |

| 4-20 mA Output | Yes |

| Field Replaceable Sensor | No |

| Auto Test Generator | None |

| Voltage Output | None |

| Power Requirements | 12-30 VDC |

| Accuracy | Generally +/-5% of value, but limited by available calibration gas accuracy |

| Operational Temperature Range | -30 to +55C |

| Operating Pressure | 7-30 PSIA |

| Warranty | 1 Year |

| Audible Alarm | No |

| Calibration | 6 Months |

| Sensor Life | 1 Year |

| Range | Gas Dependent |

| Unit Features | -4-20 mA Output -Optional Display -Can be Loop Powered - |

| Sensor Range | Gas Dependent |

| Integrated Relays | No |

| Sensor Range | Gas Dependent |

- Acid Gases

- Acetic Acid

- Acetone

- Acetylene

- Adenosine Triphosphate (ATP)

- Alcohol

- Alkalinity

- Ammonia

- Aromatic Isocyanates (TDI & MDI)

- Arsine

- Bacteria/APC

- Benzene

- Bromine

- Butane

- Carbohydrazide

- Carbon Dioxide

- Carbon Monoxide

- Chloride

- Chlorine

- Chlorine Dioxide

- Chromate

- COD

- Combustibles

- Copper

- Cyanide

- DEHA

- Detergents

- Diborane

- Dimethylamine

- E. Coli

- Ethylene Oxide

- Fluoride

- Fluorine

- Formaldehyde

- Germane

- Glutaraldehyde

- Glycol

- Hardness

- Hydrazine

- Hydride

- HydroCarbons

- Hydrogen

- Hydrogen Bromide

- Hydrogen Chloride

- Hydrogen Cyanide

- Hydrogen Fluoride

- Hydrogen Peroxide

- Hydrogen Selenide

- Hydrogen Sulfide

- Hypochlorite

- Iodine

- Iron

- Manganese

- Mercaptobenzothiazole

- Mercury

- Methane

- Molybdate

- Monochloramine

- Nitrate

- Nitric Oxide

- Nitrite

- Nitrogen Dioxide

- Nitrogen Oxides

- NMHC

- Oxygen

- Ozone

- Particulate Matter

- Peracetic Acid

- Perchloroethelyne

- pH

- Phenols

- Phosgene

- Phosphate

- Phosphine

- Silane

- Silica

- Sodium Persulfate

- Sulfate

- Sulfide

- Sulfite

- Sulfur Dioxide

- Thiosulfate

- Total Dissolved Solids (TDS)

- VOC

- Zinc